Positive Displacement Lobe Pumps for Oil Products And Chemical

Unloading

Accuvon rotary lobe pumps

Oil products and chemical unloading pumps are typical applications

in petrochemical technology. Accuvon provides its rotary lobe pumps

for oil products transportation. Pump meets theAPI676 and the

sealing system meets the API682.

Accuvon rotary lobe pump has a strong hybrid transport capacity of

gas and liquid, which can empty the products in the pipeline. In

addition the pump also allows short -time drying, has stable

unloading, simple process, and high efficiency. It is currently

widely used by large chemical companies such as Sinopec and

PetroChina.

Oil products must ensure no sparks, electrostatic.and leakage

during the transportation.Accuvon pump is equipped with brass rotor

and EPDM rotor through anti-static processing to ensure the safety

of transporting flammable and explosive and easy to corrode

products.

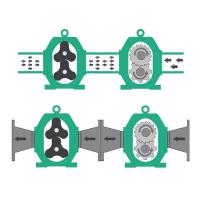

Operating Principles:

When pump lobes rotates, the space between 2 lobes increase, it

will create a partial vacuum to transfer fluid into pump chamber,

The pump shaft keeps turning, lobes will continue to create space

to delivery fluid, the tolerance between lobes and chamber ensure

the space is suitable to filled. When the pump chamber is fully

filled, the fluid will be transfer to outlet.

Specifications:

| Description | Rubber lobe pumps |

| Rotor | Rubber rotor |

| Seal | Double mechanical seal |

| Axial and radial casing protection | High-strength steel , resistant to wear |

| Drive | Electric motor |

| Material of pump | Stainless steel |

| Pressure | 0-1.2 mpa |

| Flow | 20 m³/h |

| Power | 11-55 / KW |

| Work efficiency | Up to 85% |

| Rate of flow | 0.392 l/rev |

| Self - priming | Up to 9.5m vertical / 30m horizontal |

| Medium | High-corrosive / high-viscous |

| Custom printing | Acceptable |

Construction

1. The quick-release cover

Access to all wetted parts by simply loosening four ring nuts –

maintenance without removal of pipe or drive systems.

2. The rotors

Large selection of high-quality rotors for almost pulsation-free

pumping of the medium.

3. The casing protection

Depending on its size, the BLUEline pump is available with and

completely without protection plates and liners. When pumping

abrasive media containing solids, the protection plates and liners

protect the pump casing from wear and can be replaced in a matter

of minutes.

4. The intermediate chamberand shaft seal

The large-volume quench chamber is oil-filled and ensures the

highest degree of safety. The ideal mechanical seal is selected

depending on the medium.

5. The carrier and timing gear

The high-quality and maintenancefree carrier and timing gear

guarantees a smooth and even operation of the rotors. The result is

a long service life of the pump.

Advantages

• Steel rotors with screw profile for low pulsation

• Pump is permanently technically tight

• Pressure-resistant

• Almost pulsation-free pumping

• Pumping of highly viscous media

• Resistant to solids

• High efficiency with pressures of up to 25 bar

• Pump speed can be adapted to the viscosity of the medium

• Short-term dry-run capability

• Self-priming

• Flexible flow rate

• Short-term dry-run capability

• Pumping of highly viscous media

• Pump made of stainless steel

• Quick emptying of tank

• Chemically highly resistant materials

• Small footprint

• Reversible

• Variable speeds

• Changing the rotors in a few minutes

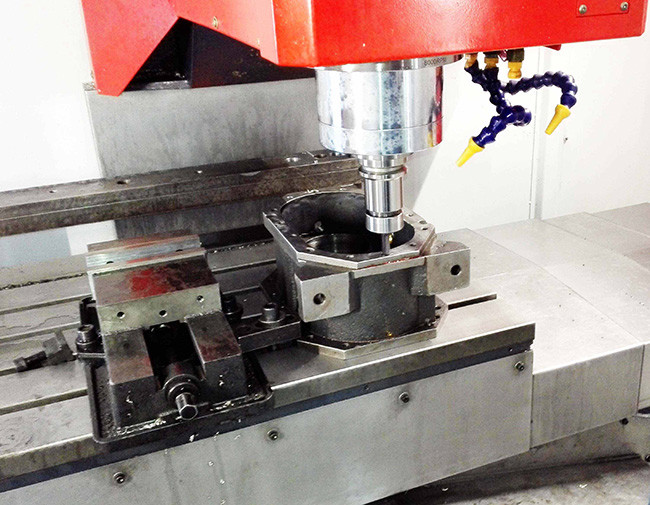

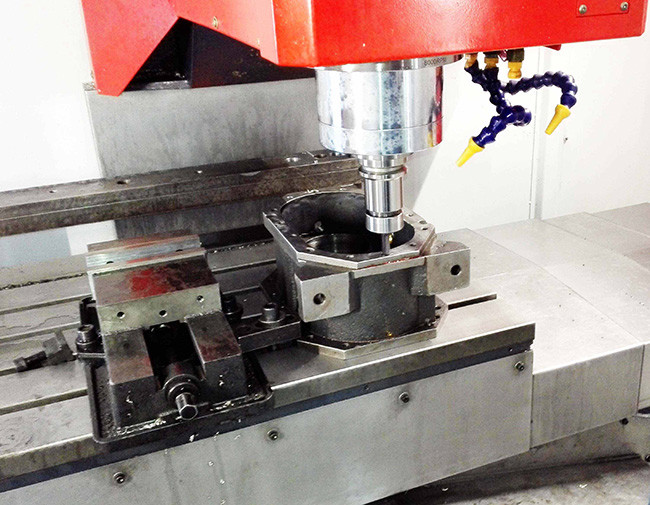

Testing Photo