316L Stainless Steel Rotor Positive Displacement Pump In Oil

Industry

Pumping in the Oil and Gas Industry

Rotary Lobe Pumps can handle abrasives, self-prime, pump thick

viscous materials, and can pump a steady GPM flow up to 2000 GPM at

steady pressures up to 150 PSI. This has lead to them being used in

many oil and gas applications. They are used for pumping clean

drilling fluid,feeding decanting centrifuges, and for treating

water produced in the upstream business. They are excellent as

booster pumps in pipelines for oil contain in abrasives and are

often applied to handle waste oil. They are a preferred solution

for pumping jet fuel and diesel from tanks recuiring a suction lift

because of their self priming capability.

We make an AP1 676 pump that complies o AP1 676 with the exception

of the seals. We manufacture an oil lubricated cartridge seal which

we have found to be long lasting and leak free that is field proven

in many tough applications.

Specifications:

| ACCUVON | rate of flow

l/rev | flow

(m³/h) | pressure

(Mpa) | speed

rpm | Flange diameter

DN mm | power

Kw |

| AC25 | 0.196 | 0.1-7 | 0-1.2 | 10-600 | DN25 | 0.75-5.5 |

| AC50 | 0.392 | 0.2-14 | 0-1.0 | 10-600 | DN50 | 1.1-5.5 |

| AC75 | 0.588 | 0.3-21 | 0-0.6 | 10-600 | DN50 | 1.1-5.5 |

| AP80 | 1.125 | 0.6-400 | 0-1.8 | 10-600 | DN80 | 3-22 |

| AP100 | 1.875 | 1.1-66 | 0-1.4 | 10-600 | DN100 | 3-22 |

| AP120 | 2.864 | 1.7-103 | 0-1.0 | 10-600 | DN100 | 3-22 |

| AP140 | 3.714 | 2.2-133 | 0-0.6 | 10-600 | DN125 | 7.5-22 |

| AF125 | 4.566 | 2.7-164 | 0-1.6 | 10-600 | DN125 | 11-55 |

| AF150 | 6.828 | 4-246 | 0-1.2 | 10-600 | DN150 | 11-55 |

| AF200 | 9.456 | 5.5-340 | 0-0.8 | 10-600 | DN200 | 11-55 |

| AX250 | 12.5 | 7.5-487 | 0-2.5 | 10-650 | DN250 | 22-315 |

| AX300 | 25 | 15-975 | 0-1.0 | 10-650 | DN300 | 30-315 |

| AX350 | 37.5 | 22.5-1463 | 0-0.6 | 10-650 | DN350 | 45-315 |

| AX450 | 50 | 30-1950 | 0-0.4 | 10-650 | DN450 | 55-315 |

| AX350D | 75 | 45-2926 | 0-0.6 | 10-650 | DN350*2 | 90-450 |

| AX450D | 100 | 60-3900 | 0-0.4 | 10-650 | DN450*2 | 110-600 |

Seal Variety

Know-how gained from several decades of pump and mechanical

seal construction has been used to build each Accuvon seal.

In order to be able to select a seal which is perfectly suited to

every single application, we offer different versions of our

singleand double-acting mechanical seals.

Mechanical seals of other manufacturers can also be installed upon

request. In addition, there is the option to integrate a quench

chamber, flush or thermosiphon system.

Seal faces, elastomers and seal casings made of different materials

make sure that the most resistant and durable materials are used

for each pumped medium. All seal types are available as a cartridge

unit and are simply replaced through the quick-release cover of the

pump.

Outstanding Range Of Material

The correct selection of material is important for the durability

of a pump. For this reason, all components of our pumps are

available in different materials. Using a modular principle, the

most resistant material most suitable for the relevant pumped

medium is selected for each pump component, from the O-ring to the

pump casing.

Unique Block Design

Each rotary lobe pump is equipped with a non-segmented pump and

gear casing. This design reflects our high quality standard and

guarantees long service life with ease of maintenance. The pump

casing can be manufactured in cast iron, cast steel, stainless

steel, duplex steel or Hastelloy.

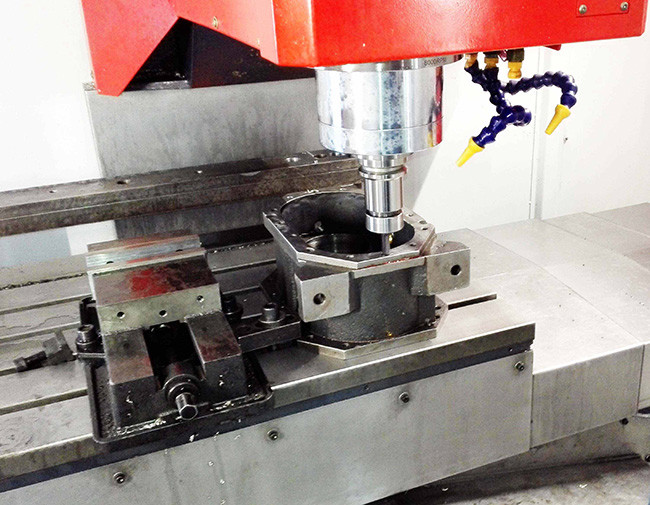

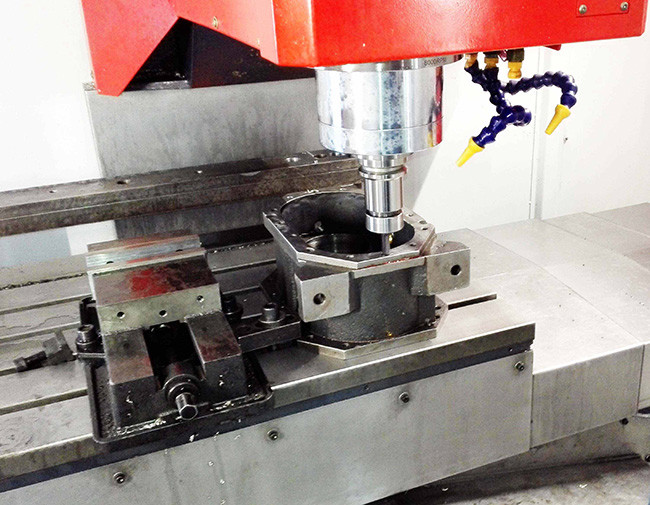

Testing Photo