Elastomer - Coated Rotor Pump For High Abrasiveness Sewage Water

Application in sewage water

Sewage water occurs in almost all industrial operations and

processes and is one of the most complex forms of wastewater. This

is due, in particular, to the demanding composition of the pumps

and conveying systems. The contents range from dissolved and

undissolved, inorganic and organic substances to acidic and basic

media, oils, and poisons.

Despite the high abrasiveness of the sewage water, the Accuvon

rotary lobe pump offers you a particularly long service life. On

the one hand, this is due to the robust and durable design and, on

the other hand, to the material reversal. While other pump

manufacturers usually have elastomer pistons rotating in a metal

housing, this pump uses steel rotary pistons. The inside of the

pump is lined with a rubber insert. This gives you a high efficient

pumping capacity when pumping industrial sewage water.

Specifications:

| ACCUVON | rate of flow

l/rev | flow

(m³/h) | pressure

(Mpa) | speed

rpm | Flange diameter

DN mm | power

Kw |

| AC25 | 0.196 | 0.1-7 | 0-1.2 | 10-600 | DN25 | 0.75-5.5 |

| AC50 | 0.392 | 0.2-14 | 0-1.0 | 10-600 | DN50 | 1.1-5.5 |

| AC75 | 0.588 | 0.3-21 | 0-0.6 | 10-600 | DN50 | 1.1-5.5 |

| AP80 | 1.125 | 0.6-400 | 0-1.8 | 10-600 | DN80 | 3-22 |

| AP100 | 1.875 | 1.1-66 | 0-1.4 | 10-600 | DN100 | 3-22 |

| AP120 | 2.864 | 1.7-103 | 0-1.0 | 10-600 | DN100 | 3-22 |

| AP140 | 3.714 | 2.2-133 | 0-0.6 | 10-600 | DN125 | 7.5-22 |

| AF125 | 4.566 | 2.7-164 | 0-1.6 | 10-600 | DN125 | 11-55 |

| AF150 | 6.828 | 4-246 | 0-1.2 | 10-600 | DN150 | 11-55 |

| AF200 | 9.456 | 5.5-340 | 0-0.8 | 10-600 | DN200 | 11-55 |

| AX250 | 12.5 | 7.5-487 | 0-2.5 | 10-650 | DN250 | 22-315 |

| AX300 | 25 | 15-975 | 0-1.0 | 10-650 | DN300 | 30-315 |

| AX350 | 37.5 | 22.5-1463 | 0-0.6 | 10-650 | DN350 | 45-315 |

| AX450 | 50 | 30-1950 | 0-0.4 | 10-650 | DN450 | 55-315 |

| AX350D | 75 | 45-2926 | 0-0.6 | 10-650 | DN350*2 | 90-450 |

| AX450D | 100 | 60-3900 | 0-0.4 | 10-650 | DN450*2 | 110-600 |

Note: Above flange is regular for each model, besides we also offer

various flange connection according to your requirements

1. Tested medium in the table: water.

2. Speed, flow rate, electrical power and pressure will be

according to different liquid properties.

3. Port size can be changed as needed.

4. ACCUVON reserves the right to change specifications without

prior notification.

Features

Self-priming.

Can dry run for limited periods of time.

Can pump heavily aerated liquids and high viscosity liquids.

Easy to maintain with all normal wearing parts able to be accessed

with the pump in-place by removing the front cover.

Helical lobes for reduced pulsation.

Heavy duty silicon carbide cartridge seals.

Working Principle of Rotary Lobe Pump:

The rotary lobe pumps we also called them lobe rotor pumps. They

are one popular transfer pump to conveying the food, beverage, pulp

and paper, chemical, pharmaceutical and so on. The rotor lobe pump

relies on two synchronously rotating rotors that generate suction

(vacuum) at the inlet during the rotation. Thereby sucking in the

material to be conveyed. Both rotors split the rotor chamber into

different spaces. Then operate in the order of 1-2-3-4. The medium

is delivered to the discharge port. In this cycle, the medium

(material) is continuously transported out by the source.

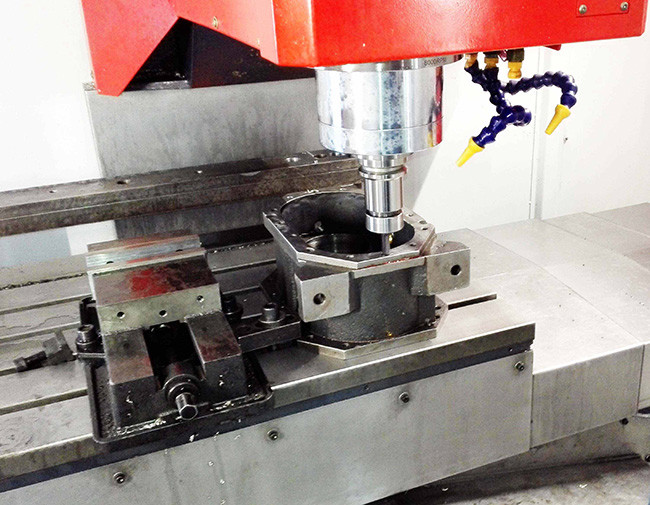

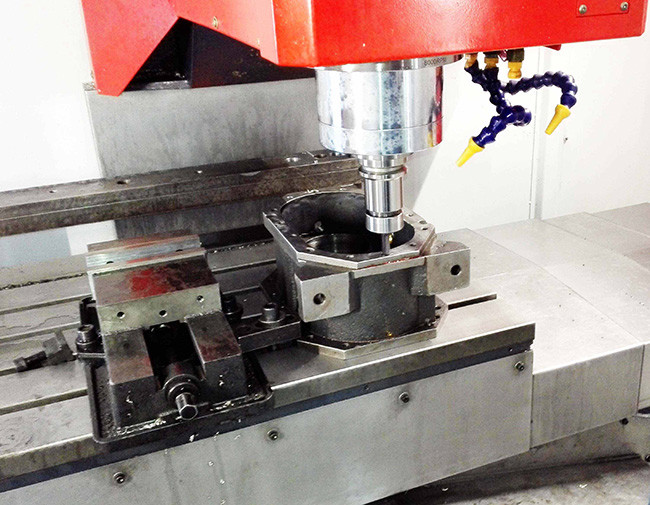

Quality inspection photos