Safe And Efficient Lobe Pump Conveying Chemical Hazardous

Substances

Application in hazardous substances

The pumping of fatty acids in the chemical industry is subject to

stringent legal requirements. With the innovative Accuvon rotary

lobe pumps, you can pump the most diverse types of hazardous

substances in compliance with all regulations. The unique design

enables you to safely empty and fill tanks or tank trucks and

ensures a particularly long service life. Even solvent-contaminated

media pose no problems for the Accuvon. This means that you expose

neither personnel, consumers, nor the environment to unnecessary

danger.

Specifications:

| ACCUVON | rate of flow

l/rev | flow

(m³/h) | pressure

(Mpa) | speed

rpm | Flange diameter

DN mm | power

Kw |

| AC25 | 0.196 | 0.1-7 | 0-1.2 | 10-600 | DN25 | 0.75-5.5 |

| AC50 | 0.392 | 0.2-14 | 0-1.0 | 10-600 | DN50 | 1.1-5.5 |

| AC75 | 0.588 | 0.3-21 | 0-0.6 | 10-600 | DN50 | 1.1-5.5 |

| AP80 | 1.125 | 0.6-400 | 0-1.8 | 10-600 | DN80 | 3-22 |

| AP100 | 1.875 | 1.1-66 | 0-1.4 | 10-600 | DN100 | 3-22 |

| AP120 | 2.864 | 1.7-103 | 0-1.0 | 10-600 | DN100 | 3-22 |

| AP140 | 3.714 | 2.2-133 | 0-0.6 | 10-600 | DN125 | 7.5-22 |

| AF125 | 4.566 | 2.7-164 | 0-1.6 | 10-600 | DN125 | 11-55 |

| AF150 | 6.828 | 4-246 | 0-1.2 | 10-600 | DN150 | 11-55 |

| AF200 | 9.456 | 5.5-340 | 0-0.8 | 10-600 | DN200 | 11-55 |

| AX250 | 12.5 | 7.5-487 | 0-2.5 | 10-650 | DN250 | 22-315 |

| AX300 | 25 | 15-975 | 0-1.0 | 10-650 | DN300 | 30-315 |

| AX350 | 37.5 | 22.5-1463 | 0-0.6 | 10-650 | DN350 | 45-315 |

| AX450 | 50 | 30-1950 | 0-0.4 | 10-650 | DN450 | 55-315 |

| AX350D | 75 | 45-2926 | 0-0.6 | 10-650 | DN350*2 | 90-450 |

| AX450D | 100 | 60-3900 | 0-0.4 | 10-650 | DN450*2 | 110-600 |

Note: Above flange is regular for each model, besides we also offer

various flange connection according to your requirements

1. Tested medium in the table: water.

2. Speed, flow rate, electrical power and pressure will be

according to different liquid properties.

3. Port size can be changed as needed.

4. ACCUVON reserves the right to change specifications without

prior notification.

Advantage

1. Rotor pump is suitable for transporting high viscosity, density

and any medium containing particle.

2. The rotational speed is low, generally keep already existing

quality not changing , any physics and chemical property won't be

changed.

3. Stainless Steel Lobe Pump can be also called colloidal pump. All

liquid flowing parts are made of stainless steel. It can transmit

high viscosity, thickness and with particle medium.

4. High pressure of out let makes sure the long distance and high

resistance transportation with stable capacity used widely in food

,chemical, industrial areas .

5. Suitable temperature: -30 °C to 200 °C.

Working Principle of Rotary Lobe Pump:

The rotary lobe pumps we also called them lobe rotor pumps. They

are one popular transfer pump to conveying the food, beverage, pulp

and paper, chemical, pharmaceutical and so on. The rotor lobe pump

relies on two synchronously rotating rotors that generate suction

(vacuum) at the inlet during the rotation. Thereby sucking in the

material to be conveyed. Both rotors split the rotor chamber into

different spaces. Then operate in the order of 1-2-3-4. The medium

is delivered to the discharge port. In this cycle, the medium

(material) is continuously transported out by the source.

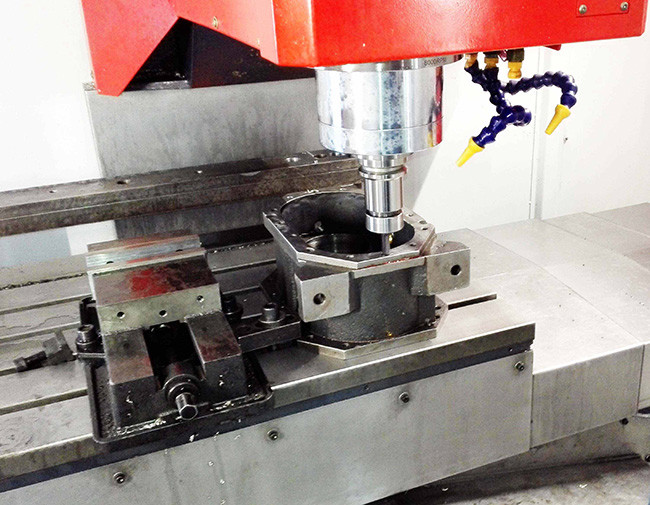

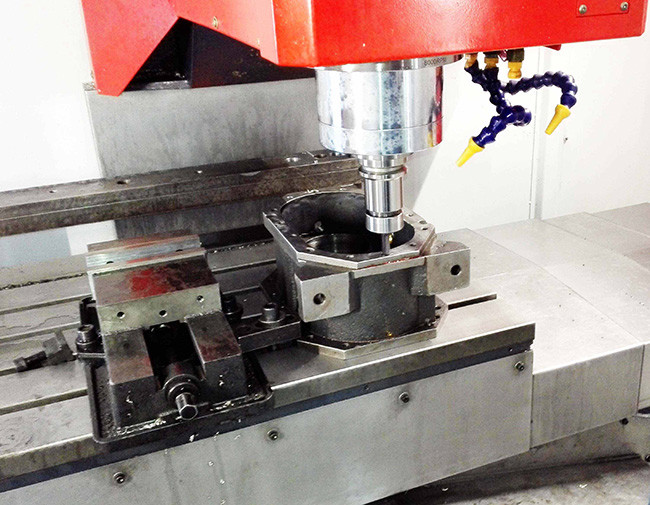

Quality inspection photos