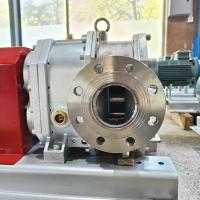

High pressure single / twin / three lobe stainless steel rotor pump

Different Kind of Rotor Options for the Rotor Lobe Pump

1.Single Lobed Rotor: More suitable for conveying media which

containing large granular materials. The breaking rate of large

granular materials is low. But on other hand it is not popular one

for used, Because its pulsation is large and pressure is low, also

the volume is small for the space of transferred materials.

2. Two-Lobed Rotor (Butterfly Rotor) More suitable for conveying

media which containing small and medium-size granular materials.

The breaking rate to these materials is low and getting slightly

pulsating. The volume is a little less than three-lobed rotor for

the space of transferred materials.

3.Three-Lobed Rotor It is widely used one rotor. The volume is

bigger than other type of rotors for the space of transferred

materials. Also each performance is higher than other rotors. Just

it has a certain rate of breakage to the particulate materials on

the transport way.

4. Multi-Lobed Rotor(4-12) The volume is more smaller for the space

of transferred materials and breaking rate more higher when the

quantity of rotary vane of rotor be increased, . Just the transport

way more stable.

Application field:

Household chemicals: Soap , toothpaste, glycerin

Fine cleaning chemicals: Fuels, pigments, additives, adhesives

Chemical fiber: Polyester fiber, rayon, polypropylene fiber.

Paper making: Starch paste, slurry, EFOAMER.

Coatings: Paints, inks, resins.

Specifications:

| ACCUVON | rate of flow

l/rev | flow

(m³/h) | pressure

(Mpa) | speed

rpm | Flange diameter

DN mm | power

Kw |

| AC25 | 0.196 | 0.1-7 | 0-1.2 | 10-600 | DN25 | 0.75-5.5 |

| AC50 | 0.392 | 0.2-14 | 0-1.0 | 10-600 | DN50 | 1.1-5.5 |

| AC75 | 0.588 | 0.3-21 | 0-0.6 | 10-600 | DN50 | 1.1-5.5 |

| AP80 | 1.125 | 0.6-400 | 0-1.8 | 10-600 | DN80 | 3-22 |

| AP100 | 1.875 | 1.1-66 | 0-1.4 | 10-600 | DN100 | 3-22 |

| AP120 | 2.864 | 1.7-103 | 0-1.0 | 10-600 | DN100 | 3-22 |

| AP140 | 3.714 | 2.2-133 | 0-0.6 | 10-600 | DN125 | 7.5-22 |

| AF125 | 4.566 | 2.7-164 | 0-1.6 | 10-600 | DN125 | 11-55 |

| AF150 | 6.828 | 4-246 | 0-1.2 | 10-600 | DN150 | 11-55 |

| AF200 | 9.456 | 5.5-340 | 0-0.8 | 10-600 | DN200 | 11-55 |

| AX250 | 12.5 | 7.5-487 | 0-2.5 | 10-650 | DN250 | 22-315 |

| AX300 | 25 | 15-975 | 0-1.0 | 10-650 | DN300 | 30-315 |

| AX350 | 37.5 | 22.5-1463 | 0-0.6 | 10-650 | DN350 | 45-315 |

| AX450 | 50 | 30-1950 | 0-0.4 | 10-650 | DN450 | 55-315 |

| AX350D | 75 | 45-2926 | 0-0.6 | 10-650 | DN350*2 | 90-450 |

| AX450D | 100 | 60-3900 | 0-0.4 | 10-650 | DN450*2 | 110-600 |

Parameter of AP 120

| Drive | Weight | Dimensions |

| KW | KG | L / mm | H / mm |

| 3 | 218 | 1323 | 394 |

| 4 | 230 | 1343 | 419 |

| 5.5 | 251 | 1433 | 454 |

| 7.5 | 263 | 1463 | 454 |

| 11 | 319 | 1553 | 509 |

| 15 | 381 | 1553 | 509 |

Design 1 | Short, straight pipe connectors with connection flange

and gasket, in mm / inches approx.

| AP 120 | DN 80 / mm | DN 100 / mm | DN 125 / mm | DN 150 / mm | DN 200 / mm |

| DIN 2633 | 146/550 | 146/550 | 176/610 | 181/620 | 251/760 |

| ANSI 150 | 161/580 | 170/598 | 210/678 | 236/730 | |

Working Principle of Rotary Lobe Pump:

The rotary lobe pumps we also called them lobe rotor pumps. They

are one popular transfer pump to conveying the food, beverage, pulp

and paper, chemical, pharmaceutical and so on. The rotor lobe pump

relies on two synchronously rotating rotors that generate suction

(vacuum) at the inlet during the rotation. Thereby sucking in the

material to be conveyed. Both rotors split the rotor chamber into

different spaces. Then operate in the order of 1-2-3-4. The medium

is delivered to the discharge port. In this cycle, the medium

(material) is continuously transported out by the source.

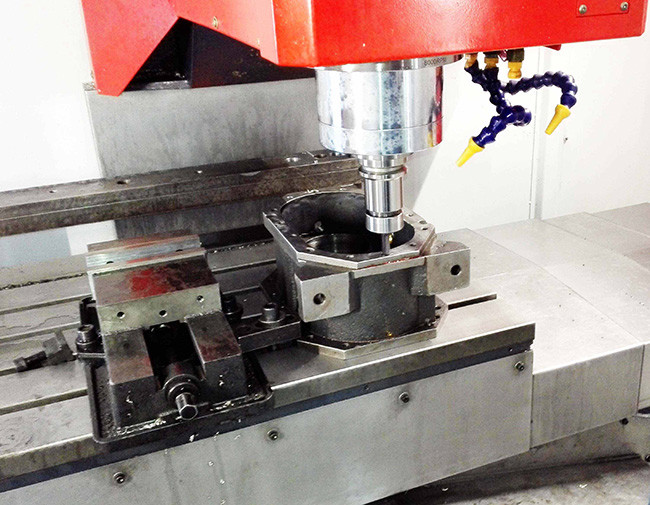

Quality inspection photos