Accuvon (Guangzhou) Pumps Co., Ltd

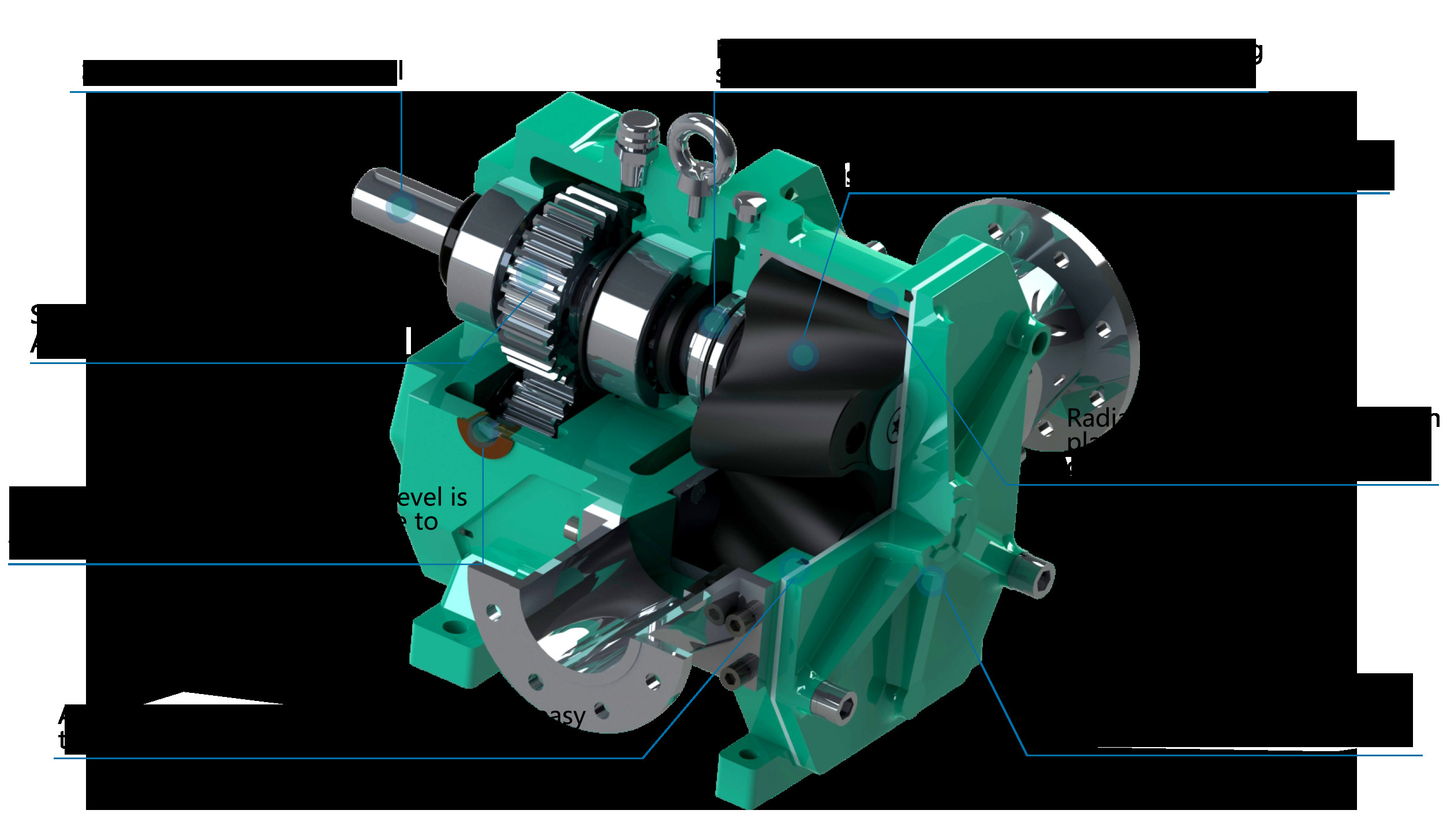

Accuvon (Guangzhou) Pumps Co., Ltd. is a Sino-German joint venture

established in 2008. It specializes in design, development,

manufacturing, sales, engineering applications and technical

services for rotor pumps. In accordance with the German DN

industrial standards and technical requirements , licensed

manufacturing and sales of ACCUVON brand rotary lobe pump in China.

In the past fifteen years, ACCUVON has focused on the field of

rotary lobe pumps, and is committed to providing customers with

professional technical support and perfect solutions. More than a

thousand projects have been implemented, with partners from all

walks of life in China.Besides, some products have been exported to

South Asia and the Middle East. With high-quality , advanced

technology and service , it has won the trust and first choice of

the industry. Up to now, the company has applied for 50+ patents,

an obtained quality management system certificate S09001,

environmental management system certificate S014001, occupational

health and safety management system certificate OHSAS18001,

high-tech enterprise certificate, high-tech product certificate (5

items) etc.

The technologies of ACCUVON pumps are mainly used in petrochemical

industry, sewage treatment, railway vacuum discharge system, biogas

energy, food waste, ship ocean, pulp and paper, light industry

etc.